Farm Machinery

Value Addition Machineries.

HeIndent Cylinder Separatorseparates whole ...

Read MoreValue Addition Machineries.

Indent Cylinder Separatorseparates whole grain and broken grain. It consists ofindents whichhelplifting the particles thatare fited in the indents. Other particles that do not fit in the indents drop out from the cell.

Cost: INR 2,50,000

Prime mover: 15-20 hp

Dry Grinding Machine

Dry grinding machine can be used grinding rice to flour. The broken rice separated by indent cylinder separator can further be value added by making rice flour. Rice flour is used to prepare different kinds of deliciouspithas. Packaging and marketing of rice flour is also a good business opportunityfor women SHGs.

Cost: INR 80,000 - 2,50,000

Prime mover: 15-20 hp motor

Rice Flake Machine

Rice flake is the husked rice that is flattened into flat, light dry flakes. These flakes of rice swell when added to liquid, whether hot or cold, as they absorb water, milk or any other liquids. The thicknesses of these flakes vary between almost translucently thin (thermo-expensive varieties) to nearly four times thicker than a normal rice grain. These are also known as POHA.

Advantages

- Better quality flakes with good texture are produced

- High strength with flawless finish

- Minimum breakage

Cost: INR 5,00,000 – 7,00,000

Prime mover: 1200kg/hr

Prime mover: Single motor driven system (20-25hp), double 'V' belt and pulley.

Rice Puff Machine

Since puffed rice is easily digested and assimilated, it has wide acceptance among a cross-section of households. It is a versatile product with an excellent market potential.

Advantages

- Makes continuous production possible.

- Less hazardous to health as no sand is used (In traditional method, the traces of sand remain on the surface of puffed rice which is hazardous to health.)

- Feasibility of prolonged operation, since the operator is not exposed to high heater smoke as in the traditional method.

Cost: INR 2,50,000 – 4,00,000

Prime mover: 350 kg/hr

Prime mover:Self-powered

Super Bag

Hermetic storage is a type of modified atmosphere ...

Read MoreSuper Bag

Hermetic storage is a type of modified atmosphere that has now been applied for the protection of stored agricultural commodities including rice, maize, pulses and other crops grain as well as seed. It is also called "sealed storage" or "airtight storage" or "sacrificial sealed storage" or "hermetic silo storage". Hermetic storage allows safe storage for periods ranging from a few weeks to many months, as well as during shipment across intercontinental distances with storage losses typically well below 1%.

Advantages

- Seed and grain can be stored hermetically

- No insect/fungus attack

- Germination rate and seed viability is maintained

- Life is 2-3 years and any commodity can be stored

Cost: INR 90/bag

Reaper

Reaper is used for harvesting of crop ...

Read MoreReaper

Reaper is used for harvesting of crop.

Benefits

Straw is not destroyed and it remains in the field as in manual harvesting

Reduces grain loss by harvesting the crop in right time

Cost: INR 1,50,000- 1,70,000

Capacity:3.5 hrs/ha

Prime mover:Self-powered

Time saving and reduction of labor-cost

Portable Rice Mill

The basic objective of a rice milling system is to ...

Read MorePortable Rice Mill

The basic objective of a rice milling system is to remove the husk and the bran layers to produce an edible, white rice kernel that is sufficiently milled and free of impurities. The milling yield and quality of rice are dependent on the quality of the paddy, the milling equipment used, and the skill of the mill operator. In comparison with traditional milling machines, the tractor-operated portable rice milling machine with rubber roller is an option for higher shelling efficiency.

Benefits

Use of rubber roller minimizes the less broken percentage (2-4%) and thus give high head rice recovery.Brown rice can be obtained. There is option for polishing to get white rice in one operation with automated elevator. It is easy for transportation for door to door service

Cost: INR 3,00,000 to 3,50,000

Capacity:1 ton per hour

Use:Milling and polishing

Diesel consumption:3 liters/hour

Prime mover:Diesel Engine (4.5 hp)

Mechanical transplanting

Mechanical transplanting of rice is the process ...

Read MoreMechanical transplanting

Mechanical transplanting of rice is the process of transplanting young rice seedlings in reduced puddling, which are grown in a mat nursery, using rice transplanter. The seedlings are raised in a layer of soil mix, arranged on a firm surface and while transplanting seedling are uprooted like a mat.

Advantages

- Timely transplanting of seedlings at the optimal age (14-18 days)

- Ensures uniform spacing, optimum plant density (2-4 seedlings per hill)

- Added productivity (5-6 q/ ha) compared to traditional methods

- Addresses the problem of labor scarcity and

- Better employment opportunities for rural youth by developing custom service center. Engagement of women in nursery enterprise

- Less drudgery for labor

Mainly two types of rice transplanter i.e., riding type & walk-behind type are in practice. Riding-type can usually transplant 6-8 lines, whereas walk-behind transplant 4-6 lines in one pass.

Cost: INR 2,40,000 – 2,85,000 (Walk-behind type) and 2,65,000 – 3,00,000 (Riding type)

Capacity: 6 hr/ha

Prime mover:Self-propelled (Petrol or diesel engine)

Mini Combine Harvester

The combine harvester or combine is a machine

Read MoreMini Combine Harvester

The combine harvester or combine is a machine that harvests different grain crops. The name combine is derived from its combining three separate operations comprising harvesting—reaping, threshing, and winnowing—into a single operation. A combine has a reaper and thresher wheel together to harvest, thresh and clean the grain from the straw in one operation.

Advantages

- Straw will not be destroyed, and it will stay on the field as manual harvesting

- Applicable for both rice and wheat harvesting

- Reaping, threshing, winnowing and packing done at a time in crop field

- Applicable for both dry and wet land

- Works in moist field also

- Harvesting capacity is more than 1 acre/hr

Cost: INR 12,00,000 – 13,00,000

Prime mover:Self-powered

Use:Harvesting, threshing, separating, cleaning and collecting

Mechanical weed control

Weed control is one of the most difficult tasks ...

Read MoreMechanical weed control

Weed control is one of the most difficult tasks on an agricultural farm. Mechanical weed control not only uproots the weeds between the crop rows but also keeps the soil surface loose, ensuring better soil aeration and water intake capacity. The power weeder is a multipurpose machine which can be used for weeding and other operations like harvesting as well as mowing.

Advantages

- Intra-row weeding in rice fields with uniform row spacing

- Save in time and labor

- Cost effective

Cost: INR 37000 – 47000

Capacity: 6 hr/ha

Prime mover: Self-powered (petrol engine)

Fuel consumption: 1lt/ hr

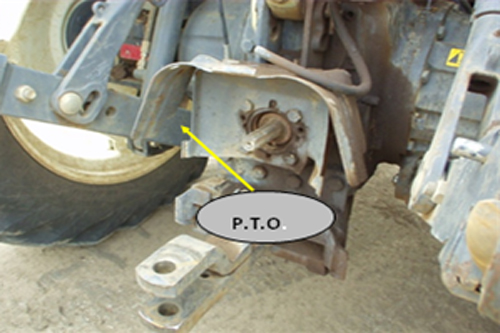

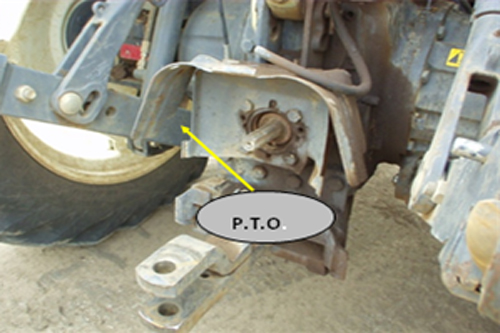

Safe Tractor Operation

When operating a tractor the following procedure ...

Read MoreSafe Tractor Operation

When operating a tractor the following procedure should be followed:

- Check the tractor and implement before going to the field.

- Lock the rear wheel brakes together when traveling on the roadway.

- Check that the field conditions are suitable before start working.

- When working in the field, unlock the brake pedals so wheels can brake separately for improved turning ability.

- Do not change gears when the tractor is moving.

- Ensure the PTO shaft is covered. As uncovered PTO shafts are a major cause of tractor accidents.

- When operating a 4-wheel drive tractor engage the front drive in the field. Do not drive on the highway with the front wheels engaged as this may cause “wind up“ which could damage the transmission.

- Select the correct operating gear. Most field operations are undertaken at ground speeds between 5-8km/hr. In a wet situation the gear selection may be lower.

- Use the hand throttle when working in the field. Foot throttles should only be used for transport situations.

- If the implement is operating at the desired depth and the engine cannot hold its engine RPM then select a lower gear.

- When operating on slopes, avoid sudden starts and stops. Operate up and down the slope on steep slopes, not across the slope. Slow down when changing directions. Do not operate where machine could slip or tip. Stay alert for holes, rocks and roots in the terrain.

Only operate as fast as you feel confident to control the equipment in a safe manner

Open Drum Thresher

This machine is more affordable and ...

Read MoreOpen Drum Thresher

This machine is more affordable and easier for such end-users to operate compared to the larger machines which may not be available in the market or accessible to smallholder farmers.

Advantages

- Specially designed for women farmers use

- Threshing and winnowing in one operation

- Portable thresher with wheel system

- Diesel engine is provided that helps to operate in rice field

- Protective concave is present to avoid accident

Cost: INR 35,000

Capacity:5-7 q/hr

Prime mover:Diesel Engine (4.5 hp)

Solar Bubble Dryer

Uses only solar energy, no operating ...

Read MoreSolar Bubble Dryer

- Uses only solar energy, no operating cost except labor

- Drying time similar to sun drying during sunny days, 2 days with cloudy sky

- Only two labor required for drying

- Grains can be dried in cloudy condition

- Protection from rain, animals, birds etc.

Cost: INR 1,50,000 for 0.5-ton and INR 2,50,000 for 1.0-ton capacity

Dimensions:25m x2m for 1ton and 15 m x 2m for 0.5 ton

Wet-DSR: By using drum seeder

Saves labor in comparison to transplanting, Reduces ...

Read MoreWet-DSR: By using drum seeder

Advantages

- Saves labor in comparison to transplanting

- Reduces in methane emission and GWP

- Requires less seed than broadcast

- Suitable to sow the pre-germinated paddy seeds directly in wetland

- Suitable option for late sowing condition in the event of early-season flood in Assam, as crop maturity is advanced by 7-10 days than in transplanting

Cost: INR 6,000- 10,000

Capacity: 5 hrs/ ha

Prime mover: Manual

Axial Flow Thresher

Threshing is the operation of separating ...

Read MoreAxial Flow Thresher

Threshing is the operation of separating the grains from the plants. These operations may be carried out in the field or on the threshing floor by hand or with the help of animals or machines.

Advantages

- In one operation it can thresh and clean the paddy

- Threshed paddy, straw and chaff collected separately

- Helps to vacate the fields earlier so that 2nd crop can be planted in sequence

Cost: INR 1,65,000 – 180,000

Capacity:16 q/hr

Prime mover:Tractor (35 hp or more)

Direct Seeding of Rice

Mechanized Dry-DSR: By using seed-cum-fertilizer drill

Read MoreDirect Seeding of Rice

Mechanized Dry-DSR: By using seed-cum-fertilizer drill

Advantages

- Saves labor, fuel energy and water

- Reduces in methane emission and global warming potential (GWP)

- Ensures seeding at optimum and uniform depth

- Maintains spacing between the rows

- Uniform seed rate throughout the field

- Good soil and seed contact- improved germination

- Provides option for fertilizer placement at the time of sowing

Conducive for intercultural and plant protection measures

Cost: INR 85,000 (tractor operated) and INR 35,000 (power tiller operated)

Capacity:2.5 hr/ha for tractor operated and 6 hr/ha for power tiller operated

Prime mover:Tractor (35 hp or more) and power tiller